The Customer

A public company specializing in the manufacture and distribution of Automotive Replacement Parts. They have been in the industry for over 100 years with facilities located through the U.S., China, Europe, and Mexico. Their local facility in Dallas Fort Worth (DFW) primarily packages and distributes product to major after-market automotive chains.

The Problem

The customer was unable to meet the demand for packaging oil coolers. Their existing solution utilized an L-bar sealer to secure the oil cooler and its supplemental components to a corrugated insert. Then the item was processed a second time through the L-Bar sealer to enclose the final package with a thin chipboard box designed for a shelf display. The L-bar sealer had issues with quality and processing capacity. Several prior suppliers attempted film and machine adjustments but the process remained insufficient.

The Analysis

A team from Leaman Container utilizing designers, engineers, and sales staff reviewed the process at the customer site. Several issues were determined:

- This specific application was outside the capability of an L-Bar as the film thickness required would not meet the marketing needs

- The L-Bar was a “monument” and a bottleneck. It was large, expensive, and slow. In addition, the cost of a 2nd machine would utilize too much floor space due to the footprint.

- There was a significant amount of movement waste due to the double handling of the product in this batch-and-queue process.

A new solution was needed which would be cost effective and be capable of scaling quickly as demand is very seasonal for the product. The team then met with the customer’s operations and marketing groups to determine key performance objectives for a new package.

The Solution

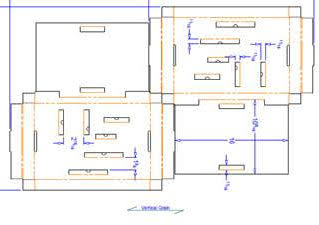

The team developed an insert and box solution which was flexible to work on several different oil cooler sizes. The insert utilized pop-up tabs to hold the product in place. The tabs are quick to pop out and allowed for different configurations depending on the cooler and its components. The outside box used a lock tab, so no film was needed to keep the box closed. In addition the no-tape design allowed every inch of the box to be utilized for branding. The design required no equipment to package. This reduced floor space for this packaging line and made scaling up production simple during peak season.

Conclusion

Leaman Containing collaborated with its customer to create a new package and process which eliminated waste, increased throughput, and had a lower material cost. The customer no longer has capacity issues and can order boxes on-demand in smaller quantities as the product is warehoused at Leaman Container. In addition, the customer’s DC box inventory is controlled through a Vendor Managed Inventory program by Leaman Container, so they always have just what they need, when they need it.