The Problem

1. Customer needed to protect collectible figures which they purchased in retail packaging from an OEM. The retail box containing the figures could not be damaged as it would diminish the collectible value of the figures. The challenge for the customer’s DC was to remove the bulk packed collectible figures and individually distribute to their nationwide network of stores. Their existing solutions was an expensive tuck top box which protected the OEM packaging and the collectible. A less expensive solution was needed.

2. The customer also had diminished sales during the prior holiday season as their supplier of protective boxes was not able to respond to extreme demand increases.

3. The customer needed to be able to scan the UPC on the OEM retail packaging after it was placed in a protective box.

Analysis

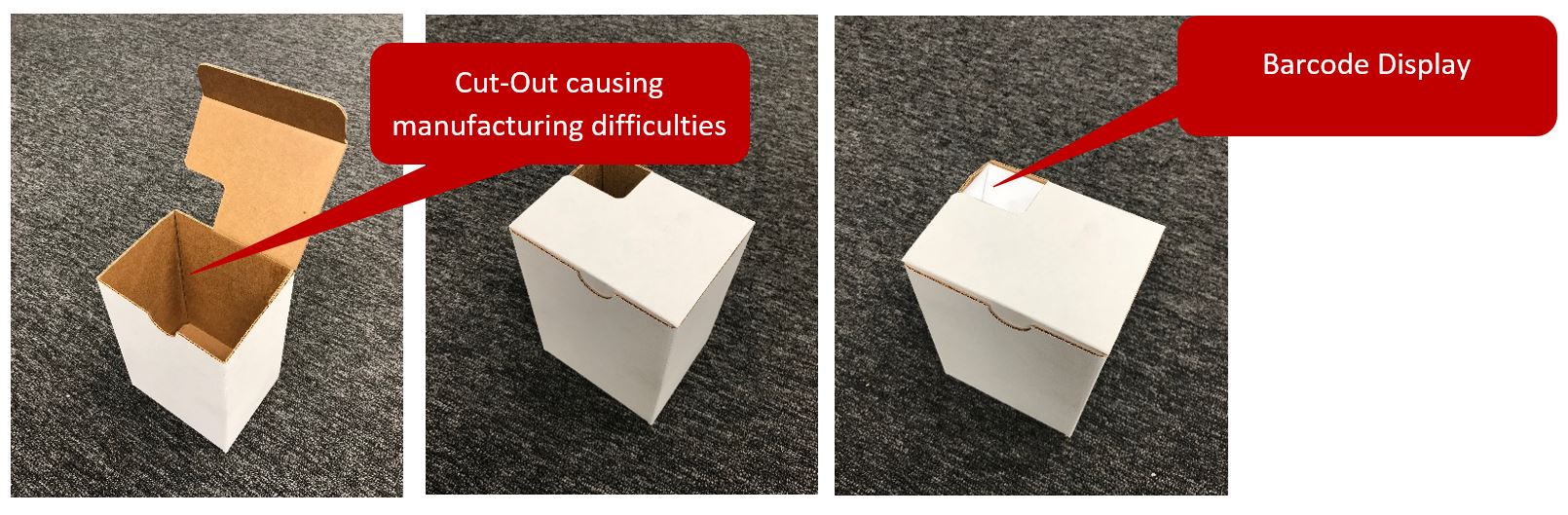

The Leaman design team reviewed the existing box and discovered the protective box pricing and delays in delivery by their current supplier was caused by a design efficiency. The particular design chosen was difficult to manufacture because the cutout on the box for scanning the OEM barcode would jam during the gluing process.

Solution

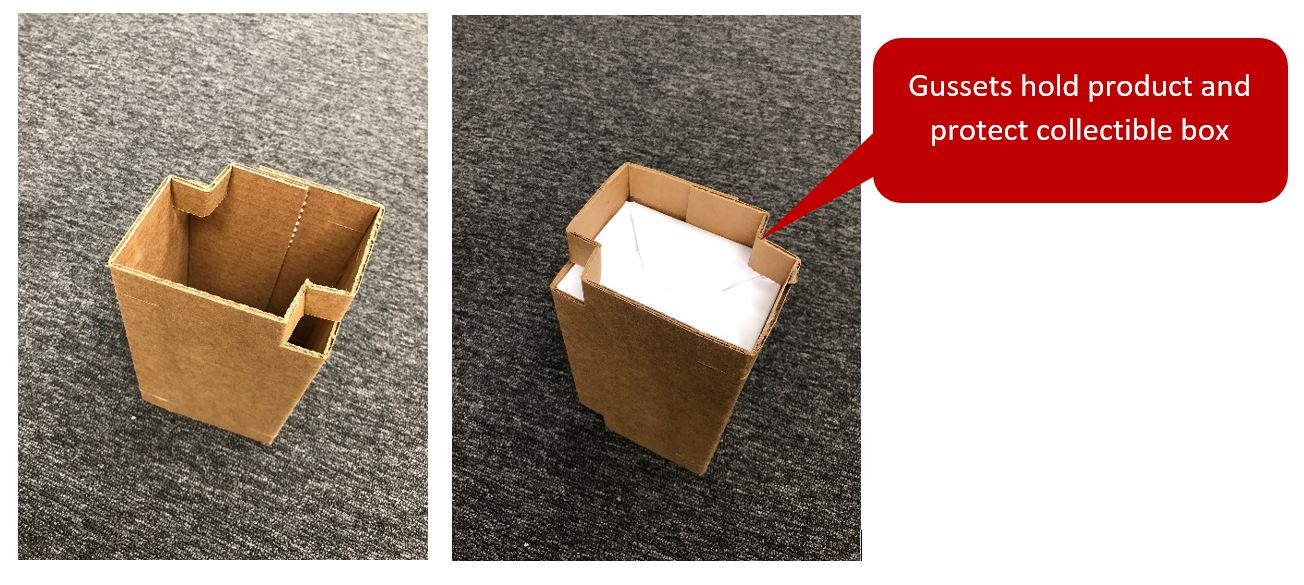

The team recommended a box with a no flaps. It used corner gussets to trap the OEM retail box within the carton. This solution drove several benefits

1. It used less material (reduced cost)

2. It was simpler to manufacture (reduced cost and Leadtime)

3. It was faster to assemble at the customer’s DC (reduced cost)

This in combination with Leaman Container’s short lead times and flexible capacity allowed the customer to supply their stores with collectibles the following Christmas and reduce the cost of the box while protecting the OEM retail packaging.